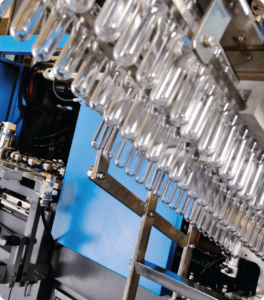

Trusted by companies all over the world

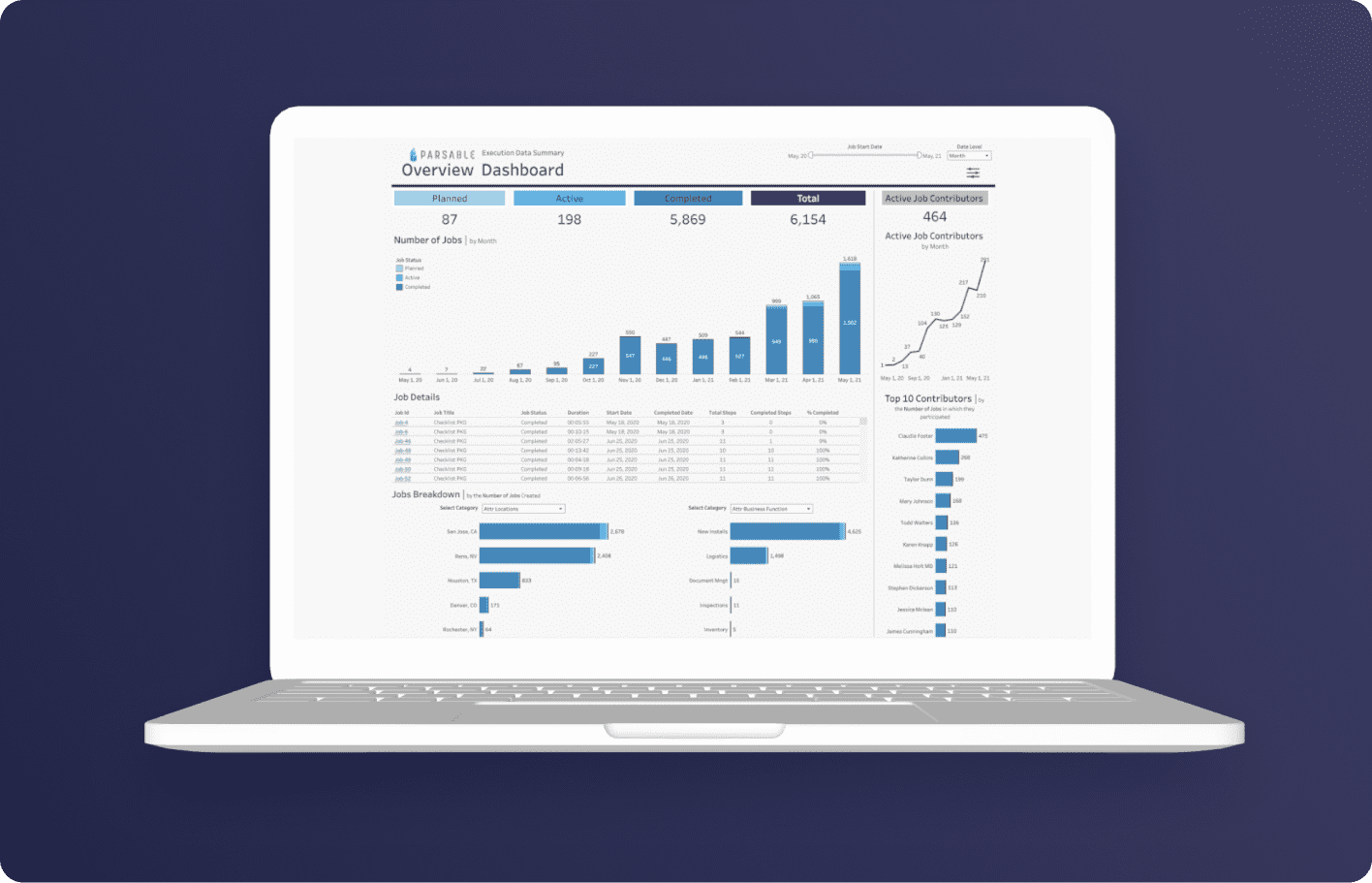

Operational Insights

Everything you need to optimize frontline operations

What you don’t know is hurting you. Parsable provides manufacturing and industrial leaders a deeper look into their operational inefficiencies with insights into how to fix them.

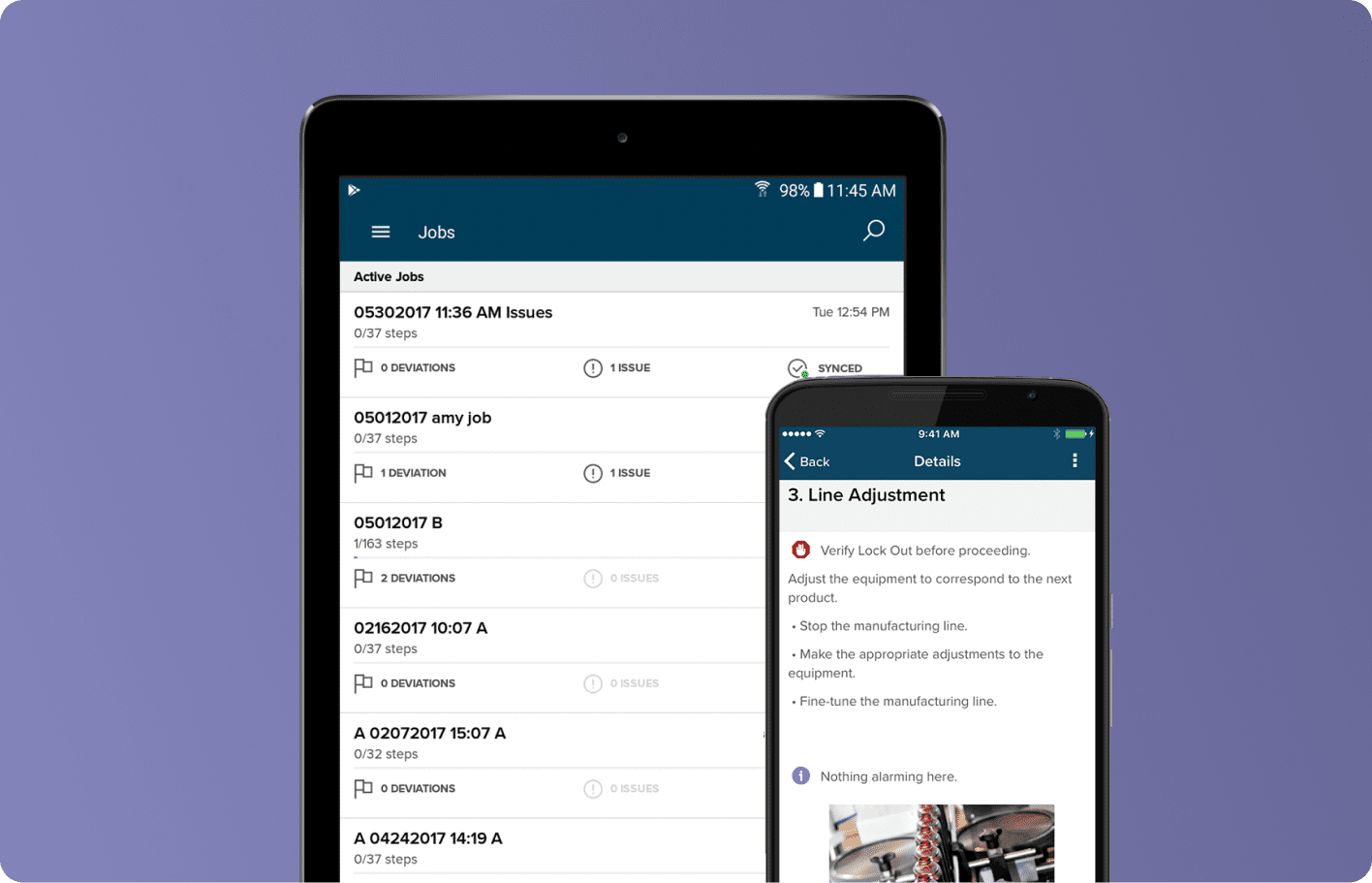

Digitize your frontline

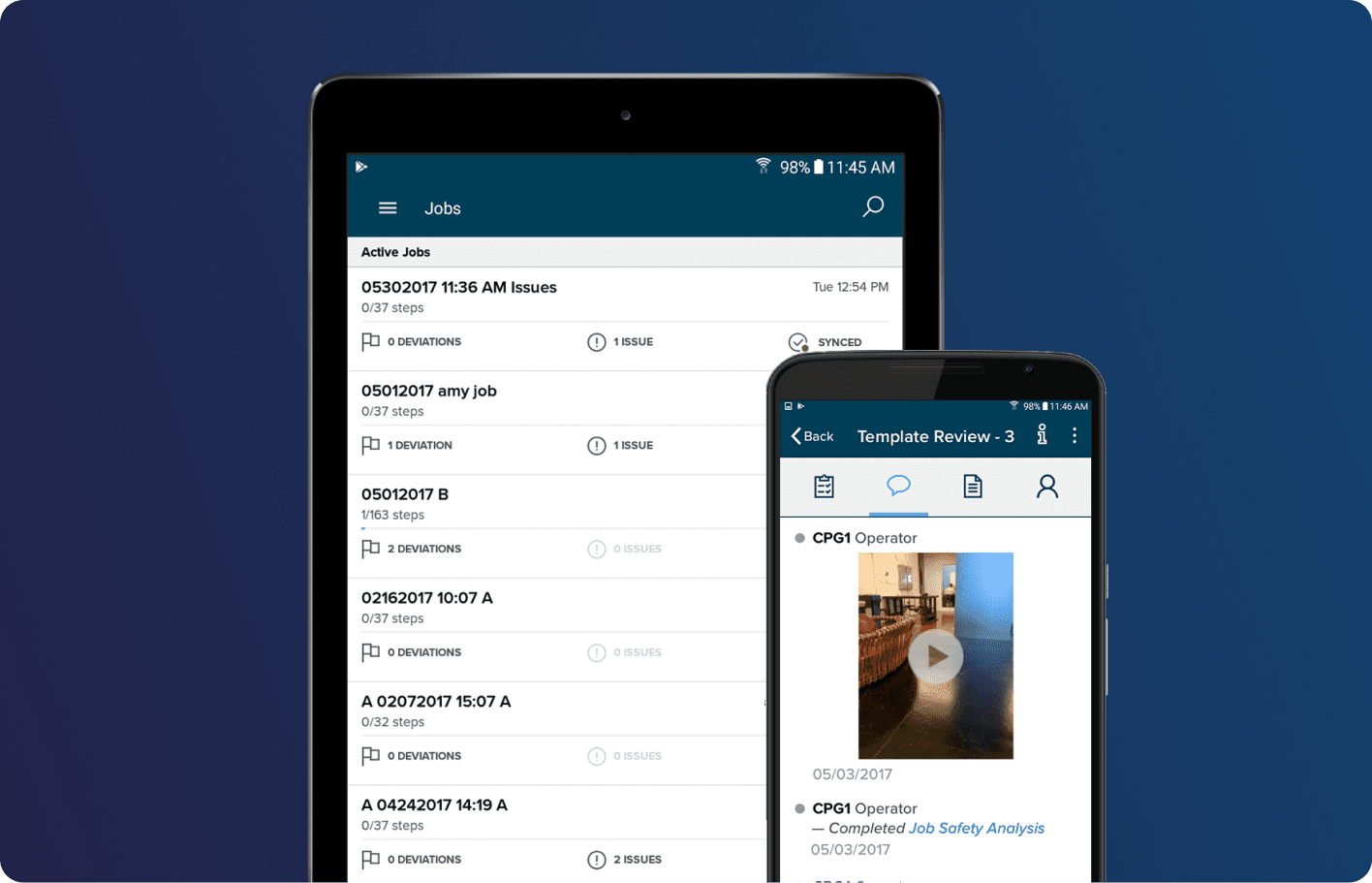

Create, update, and distribute digital work instructions worldwide with an easy-to-use authoring tool. Capture and generate work execution data and insights through Parsable’s mobile app for industrial operations.

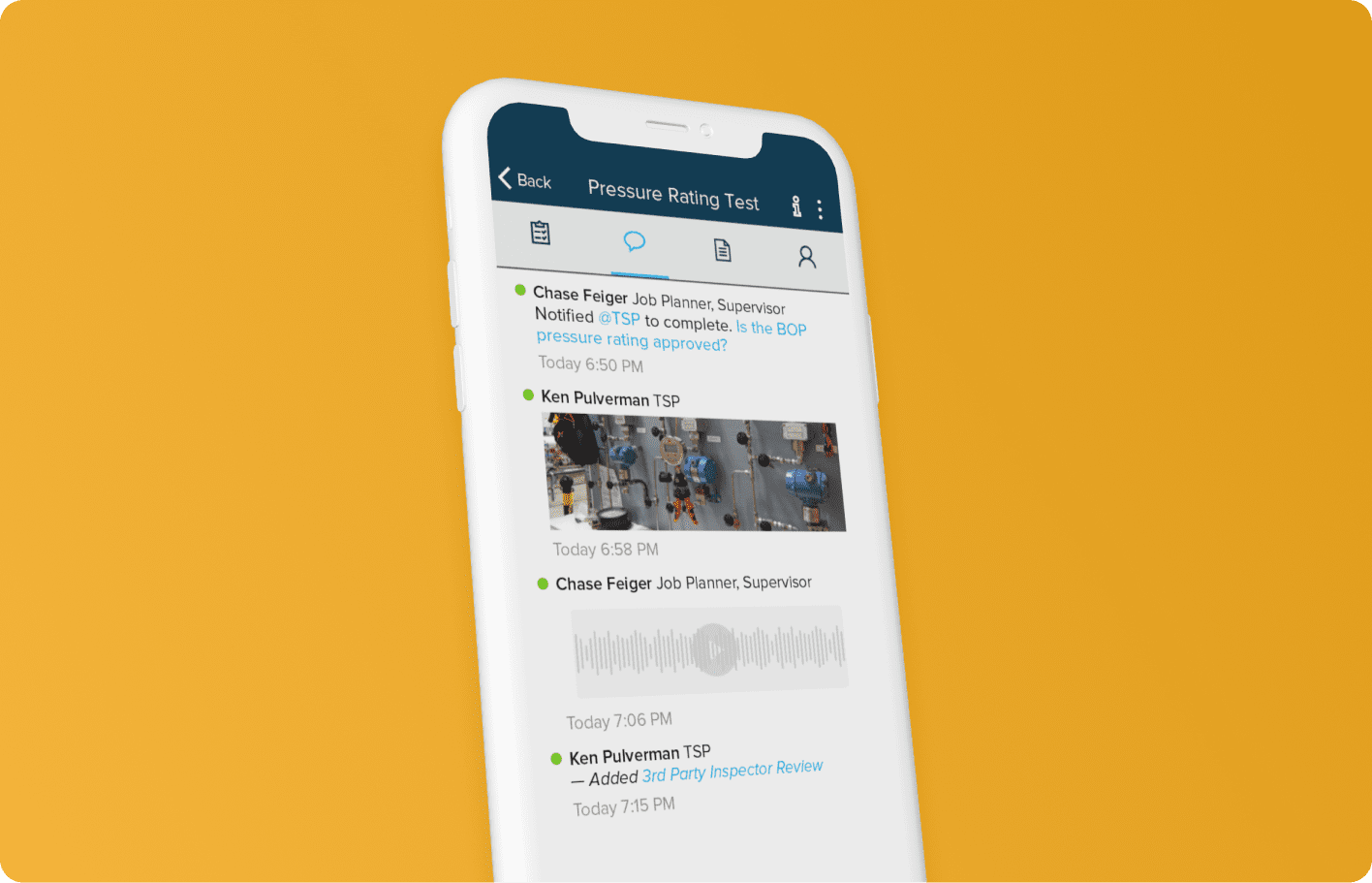

Engage your workforce

Enable collaboration amongst your teams. Post a question, report an issue, or share expertise through assignment-specific messaging portals.

Unlock activity data

Leverage near real-time data to unlock actionable insights into inefficiencies impacting operational results. Use flexible configuration options to classify your data for easier organization storage, and analysis.

Transform your operations

Achieve impressive results by enabling your workforce to identify, implement, and sustain improvements – continuously.

Audits & Inspections

Automate the processing and tracking of all data associated with your frontline’s routine audits, inspections, checklists, and more.

Workflow & Collaboration

Enable frontline teams to work together more efficiently to shorten the time required for line changeovers, plant turnarounds, shift handoffs, and more.

Compliance & Adherence

Make your frontline operations audit proof by ensuring that what needs to get done always gets done.

On-the-Job Training

Spread expertise by upskilling workers in the moment with just-in-time learning, one-point lessons, and data-backed best practices.

Real-Time Integrations

Update your business-critical systems in real time and build resiliency, adaptability, and agility into your frontline operations.

Insights & Process Optimization

Unlock insights into inefficiencies impacting frontline processes and workflows, then take action to continuously improve frontline operations.

Operational Insights

Connect your teams and drive operational excellence

Industrial executives and leaders

Leverage human work execution data to improve operations and build a sustainable future.

Functional experts

Create, test, deploy, and improve critical SOPs with a no-code platform.

Frontline workers and supervisors

Learn, work, and collaborate across digital business processes to always get work done right.